This instructables is usefull if:

* you’ve got your arduino with atmega168 and you bought an atmega328 at you local electronics store. It doesn’t have an arduino bootloader

* you want to make a project that doesn’t use arduino – just a regular AVR chip (like the USBTinyISP) – you have a clean attiny2313/attiny48 etc that you want to burn firmware on.

Normally you would have to have an ISP (In System Programmer) like USBTinyISP to program your new chip. Having the arduino you can teach it to be a programmer thank to a great work done by Randall Bohn. He created Mega-ISP – an arduino sketch that works like a programmer.

* a chip that you want to program (tested with atmega8,atmega168,atmega368, attiny2313, attiny13)

* a breadboard or a board with ISP header

* 3 leds + 3 resistors

* breadboard wires

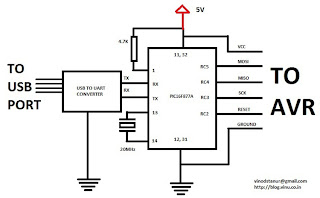

You can plug your avr chip to a breadboard and connect 5v and GND to the respective pins (check the datasheet!) + a pullup resistor to reset and wire pins from you arduino to the chip.

These are the lines on Arduino and their function

13 – SCK

12 – MISO

11 – MOSI

10 – RST (Reset)

Or you can make a 2x3pin ISP header that you can plug into a board that provides one (another arduino board).

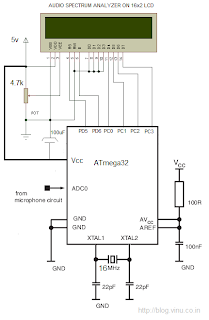

The pinout for the ISP header is on the third image

There are 3 leds to indicate the status of the programmer.

pin 9 – blue led – its the hearbeat of the programmer.

pin 8 – red led – indicates an error

pin 7 – green led – indicates that the programming is taking place

(i was lazy so i didn’t match the colors in my setup)

Here are the drawings made in Fritzing

You can alsa make a MEGA-isp shield. Yaroslav Osadchyy designed the shield in eagle. You can get the eagle files on his site: http://drug123.org.ua/mega-isp-shield/

Unpack it and run arduino ide and open avrisp.pde.

Upload it to your arduino board.

Heartbeat led should start beating.

For more detail, Click here...

* you’ve got your arduino with atmega168 and you bought an atmega328 at you local electronics store. It doesn’t have an arduino bootloader

* you want to make a project that doesn’t use arduino – just a regular AVR chip (like the USBTinyISP) – you have a clean attiny2313/attiny48 etc that you want to burn firmware on.

Normally you would have to have an ISP (In System Programmer) like USBTinyISP to program your new chip. Having the arduino you can teach it to be a programmer thank to a great work done by Randall Bohn. He created Mega-ISP – an arduino sketch that works like a programmer.

Step: 1 What do you need ?

* a working Arduino (or a clone – i’m using the BBB – BareBonesBoard and a RBBB – RealBareBonesBoard by ModernDevices)

* a chip that you want to program (tested with atmega8,atmega168,atmega368, attiny2313, attiny13)

* a breadboard or a board with ISP header

* 3 leds + 3 resistors

* breadboard wires

Step: 2 Making the mega-isp programmer on a breadboard

There are two ways to connect your Arduino to program a chip.

You can plug your avr chip to a breadboard and connect 5v and GND to the respective pins (check the datasheet!) + a pullup resistor to reset and wire pins from you arduino to the chip.

These are the lines on Arduino and their function

13 – SCK

12 – MISO

11 – MOSI

10 – RST (Reset)

Or you can make a 2x3pin ISP header that you can plug into a board that provides one (another arduino board).

The pinout for the ISP header is on the third image

There are 3 leds to indicate the status of the programmer.

pin 9 – blue led – its the hearbeat of the programmer.

pin 8 – red led – indicates an error

pin 7 – green led – indicates that the programming is taking place

(i was lazy so i didn’t match the colors in my setup)

Here are the drawings made in Fritzing

You can alsa make a MEGA-isp shield. Yaroslav Osadchyy designed the shield in eagle. You can get the eagle files on his site: http://drug123.org.ua/mega-isp-shield/

Step: 3 Uploading the sketch

Download the sketch from mega-isp google code.(avrisp.03.zip at the time of writing).Unpack it and run arduino ide and open avrisp.pde.

Upload it to your arduino board.

Heartbeat led should start beating.

For more detail, Click here...